نیما 17 (42 ملی میٹر) ہائبرڈ سٹیپر موٹر، بائی پولر، 4 لیڈ، ACME لیڈ اسکرو، سٹیپ اینگل 1.8°، لمبی زندگی، اعلی کارکردگی۔

نیما 17 (42 ملی میٹر) ہائبرڈ سٹیپر موٹر، بائی پولر، 4 لیڈ، ACME لیڈ اسکرو، سٹیپ اینگل 1.8°، لمبی زندگی، اعلی کارکردگی۔

یہ 42mm ہائبرڈ سٹیپر موٹر تین اقسام میں دستیاب ہے: بیرونی طور پر چلنے والی، تھرو ایکسس، اور تھرو فکسڈ ایکسس۔ آپ اپنی مخصوص ضروریات کے مطابق انتخاب کر سکتے ہیں۔

تفصیل

| پروڈکٹ کا نام | 42 ملی میٹر ہائبرڈ سٹیپر موٹرز |

| ماڈل | VSM42HSM |

| قسم | ہائبرڈ سٹیپر موٹرز |

| سٹیپ اینگل | 1.8° |

| وولٹیج (V) | 2/2.6/ 3.3 |

| موجودہ (A) | 1.5/2.5 |

| مزاحمت (اوہم) | 0.8/1.8/2.2 |

| انڈکٹنس (mH) | 1.8/2.8/4.6 |

| لیڈ وائرز | 4 |

| موٹر کی لمبائی (ملی میٹر) | 34/48/46 |

| محیطی درجہ حرارت | -20℃ ~ +50℃ |

| درجہ حرارت میں اضافہ | 80K زیادہ سے زیادہ |

| ڈائی الیکٹرک طاقت | 1mA زیادہ سے زیادہ @ 500V، 1KHz، 1Sec۔ |

| موصلیت مزاحمت | 100MΩ منٹ @500Vdc |

سرٹیفیکیشنز

برقی پیرامیٹرز:

| موٹر سائز | وولٹیج /فیز (V) | کرنٹ /فیز (ا) | مزاحمت /فیز (Ω) | انڈکٹنس /فیز (mH) | کی تعداد لیڈ وائرز | روٹر جڑتا (g.cm2) | موٹر وزن (جی) | موٹر کی لمبائی L (ملی میٹر) |

| 42 | 2.6 | 1.5 | 1.8 | 2.6 | 4 | 35 | 250 | 34 |

| 42 | 3.3 | 1.5 | 2.2 | 4.6 | 4 | 55 | 290 | 40 |

| 42 | 2 | 2.5 | 0.8 | 1.8 | 4 | 70 | 385 | 48 |

| 42 | 2.5 | 2.5 | 1 | 2.8 | 4 | 105 | 450 | 60 |

لیڈ سکرو کی وضاحتیں اور کارکردگی کے پیرامیٹرز

| قطر (ملی میٹر) | لیڈ (ملی میٹر) | قدم (ملی میٹر) | سیلف لاکنگ فورس کو بند کریں۔ (این) |

| 6.35 | 1.27 | 0.00635 | 150 |

| 6.35 | 3.175 | 0.015875 | 40 |

| 6.35 | 6.35 | 0.03175 | 15 |

| 6.35 | 12.7 | 0.0635 | 3 |

| 6.35 | 25.4 | 0.127 | 0 |

نوٹ: مزید لیڈ سکرو وضاحتیں کے لئے، براہ مہربانی ہم سے رابطہ کریں.

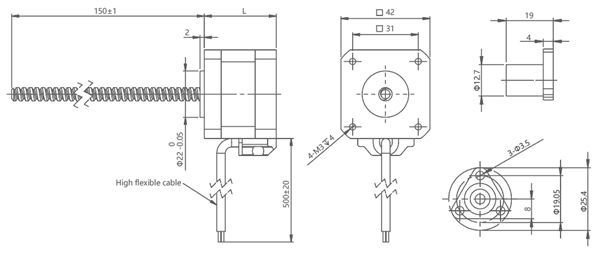

VSM42HSM معیاری بیرونی موٹر آؤٹ لائن ڈرائنگ:

نوٹس:

لیڈ سکرو کی لمبائی اپنی مرضی کے مطابق کیا جا سکتا ہے

اپنی مرضی کے مطابق مشینی لیڈ سکرو کے آخر میں قابل عمل ہے۔

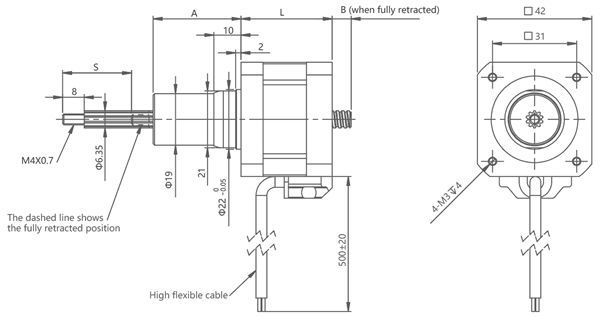

42 ملی میٹر ہائبرڈ سٹیپر موٹرز معیاری کیپٹیو موٹر آؤٹ لائن ڈرائنگ

نوٹس:

اپنی مرضی کے مطابق مشینی لیڈ سکرو کے آخر میں قابل عمل ہے۔

| اسٹروک ایس (ملی میٹر) | طول و عرض اے (ملی میٹر) | طول و عرض B (ملی میٹر) | |||

| L = 34 | L = 40 | L = 48 | L = 60 | ||

| 12.7 | 20.6 | 6.4 | 0.4 | 0 | 0 |

| 19.1 | 27 | 12.8 | 6.8 | 0 | 0 |

| 25.4 | 33.3 | 19.1 | 13.1 | 5.1 | 0 |

| 31.8 | 39.7 | 25.5 | 19.5 | 11.5 | 0 |

| 38.1 | 46 | 31.8 | 25.8 | 17.8 | 5.8 |

| 50.8 | 58.7 | 44.5 | 38.5 | 30.5 | 18.5 |

| 63.5 | 71.4 | 57.2 | 51.2 | 43.2 | 31.2 |

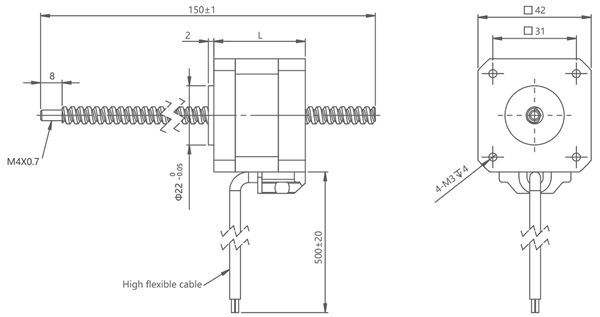

42 ملی میٹر ہائبرڈ سٹیپر موٹر اسٹینڈرڈ تھرو فکسڈ موٹر آؤٹ لائن ڈرائنگ

نوٹس:

لیڈ سکرو کی لمبائی اپنی مرضی کے مطابق کیا جا سکتا ہے

اپنی مرضی کے مطابق مشینی لیڈ سکرو کے آخر میں قابل عمل ہے۔

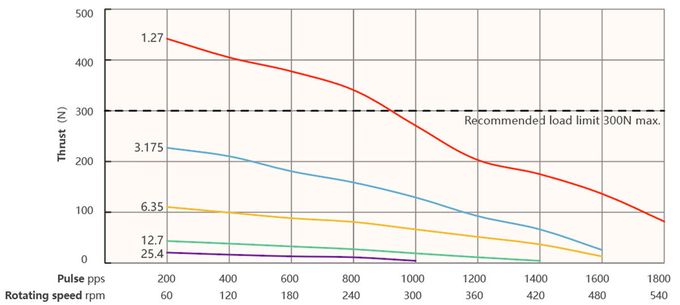

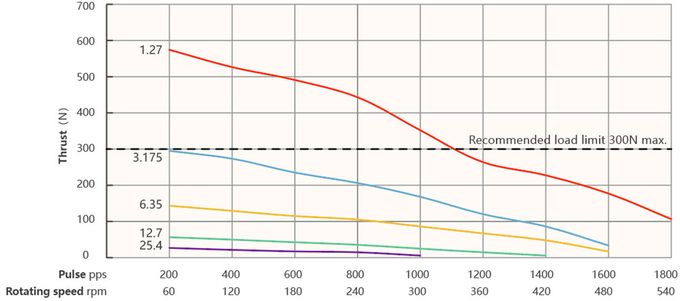

رفتار اور زور وکر:

42 سیریز 34 ملی میٹر موٹر کی لمبائی بائپولر ہیلی کاپٹر ڈرائیو

100% کرنٹ پلس فریکوئنسی اور تھرسٹ وکر (Φ6.35mm لیڈ سکرو)

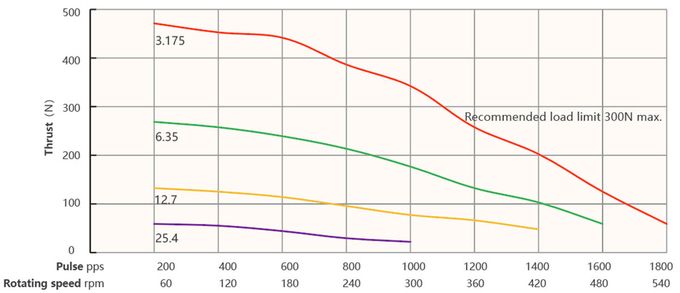

42 سیریز 40 ملی میٹر موٹر کی لمبائی بائپولر ہیلی کاپٹر ڈرائیو

100% کرنٹ پلس فریکوئنسی اور تھرسٹ وکر (Φ6.35mm لیڈ سکرو)

| لیڈ (ملی میٹر) | لکیری رفتار (ملی میٹر/سیکنڈ) | ||||||||

| 1.27 | 1.27 | 2.54 | 3.81 | 5.08 | 6.35 | 7.62 | 8.89 | 10.16 | 11.43 |

| 3.175 | 3.175 | 6.35 | 9.525 | 12.7 | 15.875 | 19.05 | 22.225 | 25.4 | 28.575 |

| 6.35 | 6.35 | 12.7 | 19.05 | 25.4 | 31.75 | 38.1 | 44.45 | 50.8 | 57.15 |

| 12.7 | 12.7 | 25.4 | 38.1 | 50.8 | 63.5 | 76.2 | 88.9 | 101.6 | 114.3 |

| 25.4 | 25.4 | 50.8 | 76.2 | 101.6 | 127 | 152.4 | 177.8 | 203.2 | 228.6 |

ٹیسٹ کی شرط:

ہیلی کاپٹر ڈرائیو، کوئی ریمپنگ نہیں، آدھا مائیکرو اسٹیپنگ، ڈرائیو وولٹیج 40V

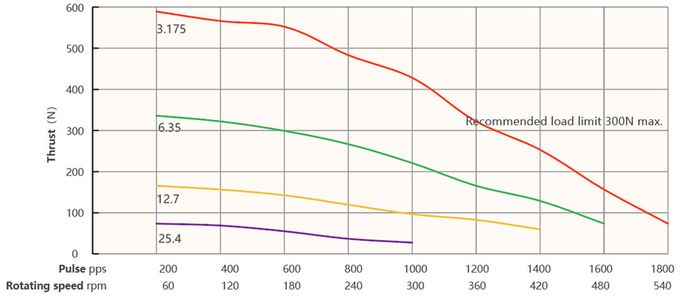

42 سیریز 48 ملی میٹر موٹر کی لمبائی بائپولر ہیلی کاپٹر ڈرائیو

100% کرنٹ پلس فریکوئنسی اور تھرسٹ وکر (Φ6.35mm لیڈ سکرو)

42 سیریز 60 ملی میٹر موٹر کی لمبائی بائپولر ہیلی کاپٹر ڈرائیو

100% کرنٹ پلس فریکوئنسی اور تھرسٹ وکر (Φ6.35mm لیڈ سکرو)

| لیڈ (ملی میٹر) | لکیری رفتار (ملی میٹر/سیکنڈ) | ||||||||

| 1.27 | 1.27 | 2.54 | 3.81 | 5.08 | 6.35 | 7.62 | 8.89 | 10.16 | 11.43 |

| 3.175 | 3.175 | 6.35 | 9.525 | 12.7 | 15.875 | 19.05 | 22.225 | 25.4 | 28.575 |

| 6.35 | 6.35 | 12.7 | 19.05 | 25.4 | 31.75 | 38.1 | 44.45 | 50.8 | 57.15 |

| 12.7 | 12.7 | 25.4 | 38.1 | 50.8 | 63.5 | 76.2 | 88.9 | 101.6 | 114.3 |

| 25.4 | 25.4 | 50.8 | 76.2 | 101.6 | 127 | 152.4 | 177.8 | 203.2 | 228.6 |

ٹیسٹ کی شرط:

ہیلی کاپٹر ڈرائیو، کوئی ریمپنگ نہیں، آدھا مائیکرو اسٹیپنگ، ڈرائیو وولٹیج 40V

درخواست کے علاقے

آٹومیشن کا سامان:42mm ہائبرڈ سٹیپر موٹرز بڑے پیمانے پر آٹومیشن آلات کی ایک قسم میں استعمال ہوتی ہیں، بشمول خودکار پیکیجنگ مشینیں، خودکار پروڈکشن لائنز، مشین ٹولز اور پرنٹنگ کا سامان۔ وہ درست پوزیشن کنٹرول اور اعلی ٹارک آؤٹ پٹ فراہم کرتے ہیں تاکہ درست حرکت اور وشوسنییتا کے لیے آٹومیشن آلات کی ضروریات کو پورا کیا جا سکے۔

3D پرنٹرز:42mm ہائبرڈ سٹیپر موٹرز 3D پرنٹرز میں کلیدی کردار ادا کرتی ہیں۔ وہ اعلی صحت سے متعلق پوزیشن کنٹرول کے لئے پرنٹ ہیڈ کو چلانے اور پرنٹنگ کے عین مطابق کاموں کو محسوس کرنے کے لئے استعمال ہوتے ہیں۔ یہ موٹرز اچھی پوزیشننگ کی درستگی اور بھروسے کی پیش کش کرتی ہیں، جو 3D پرنٹرز کی کارکردگی اور پرنٹ کوالٹی کو بہتر بنانے میں مدد کرتی ہے۔

طبی آلات:42 ملی میٹر ہائبرڈ سٹیپر موٹرز بڑے پیمانے پر طبی آلات میں استعمال ہوتی ہیں۔ مثال کے طور پر، طبی امیجنگ آلات میں (مثال کے طور پر، CT سکینر، ایکس رے مشینیں)، یہ موٹریں گھومنے والے پلیٹ فارمز اور حرکت پذیر حصوں کو کنٹرول کرنے کے لیے استعمال ہوتی ہیں۔ اس کے علاوہ، وہ طبی آلات جیسے سرجیکل روبوٹ، سرنج، اور خودکار نمونہ پروسیسنگ میں درست پوزیشن کنٹرول کے لیے استعمال ہوتے ہیں۔

روبوٹکس:42 ملی میٹر ہائبرڈ سٹیپر موٹرز روبوٹکس میں اہم کردار ادا کرتی ہیں۔ ان کا استعمال روبوٹ کے جوڑوں کو چلانے کے لیے کیا جا سکتا ہے، جو کہ اعلیٰ درست پوزیشن کنٹرول اور ٹارک آؤٹ پٹ فراہم کرتے ہیں۔ روبوٹکس ایپلی کیشنز میں صنعتی روبوٹس، سروس روبوٹس، اور میڈیکل روبوٹس شامل ہیں۔

آٹوموٹو:42mm ہائبرڈ سٹیپر موٹرز آٹوموٹو آلات میں ایپلی کیشنز ہیں. وہ آٹوموبائل کے اندر مختلف کنٹرول سسٹمز میں استعمال ہوتے ہیں، جیسے آٹوموٹیو سیٹ ایڈجسٹمنٹ، ونڈو لفٹنگ اور لوئرنگ، اور ریئر ویو مرر ایڈجسٹمنٹ۔ یہ موٹریں آٹوموٹو آلات کے مناسب آپریشن کو یقینی بنانے کے لیے اعلیٰ درست پوزیشن کنٹرول اور قابل اعتماد کارکردگی فراہم کرتی ہیں۔

اسمارٹ ہوم اور کنزیومر الیکٹرانکس:42mm ہائبرڈ سٹیپر موٹرز سمارٹ ہوم اور کنزیومر الیکٹرانکس میں استعمال ہوتی ہیں۔ درست پوزیشن کنٹرول اور حرکت کے افعال فراہم کرنے کے لیے انہیں سمارٹ ڈور لاک، کیمرہ ہیڈز، سمارٹ پردے، روبوٹک ویکیوم کلینر وغیرہ جیسے آلات میں استعمال کیا جا سکتا ہے۔

مندرجہ بالا ایپلی کیشنز کے علاوہ، 42 ملی میٹر ہائبرڈ سٹیپر موٹرز کو ٹیکسٹائل آلات، سیکورٹی مانیٹرنگ سسٹم، اسٹیج لائٹنگ کنٹرول، اور دیگر شعبوں میں بھی استعمال کیا جا سکتا ہے جن میں درست پوزیشن کنٹرول اور قابل اعتماد کارکردگی کی ضرورت ہوتی ہے۔ مجموعی طور پر، 42 ملی میٹر ہائبرڈ سٹیپر موٹرز ایک سے زیادہ صنعتوں میں ایپلی کیشنز کی ایک وسیع رینج رکھتی ہیں۔

فائدہ

کم رفتار پر ٹارک:42mm ہائبرڈ سٹیپر موٹرز کم رفتار پر بہترین ٹارک کارکردگی دکھاتی ہیں۔ وہ ہائی ہولڈنگ ٹارک پیدا کر سکتے ہیں، انہیں شروع کرنے اور بہت کم رفتار پر بھی آسانی سے کام کرنے کے قابل بناتے ہیں۔ یہ خصوصیت انہیں ایسی ایپلی کیشنز کے لیے موزوں بناتی ہے جن میں عین کنٹرول اور سست حرکت کی ضرورت ہوتی ہے، جیسے روبوٹکس، آٹومیشن کا سامان، اور طبی آلات۔

پوزیشننگ کی درستگی:یہ موٹریں اعلی پوزیشننگ کی درستگی پیش کرتی ہیں۔ ان کے ٹھیک قدم کے حل کے ساتھ، وہ عین مطابق پوزیشننگ اور درست موشن کنٹرول حاصل کر سکتے ہیں۔ یہ ان ایپلی کیشنز میں بہت اہم ہے جو درست پوزیشننگ کا مطالبہ کرتے ہیں، جیسے CNC مشینیں، 3D پرنٹرز، اور پک اینڈ پلیس سسٹم۔

سیلف لاکنگ کی صلاحیت:ہائبرڈ سٹیپر موٹرز میں سیلف لاک کرنے کی صلاحیت ہوتی ہے جب وائنڈنگز متحرک نہ ہوں۔ اس کا مطلب یہ ہے کہ وہ بجلی کی کھپت کے بغیر اپنی پوزیشن برقرار رکھ سکتے ہیں، جو ان ایپلی کیشنز میں فائدہ مند ہے جہاں پاور کے بغیر پوزیشن پر فائز ہونا ضروری ہے، جیسے کہ روبوٹک ہتھیاروں یا پوزیشنرز میں۔

لاگت سے موثر:42 ملی میٹر ہائبرڈ سٹیپر موٹرز بہت سی ایپلی کیشنز کے لیے سرمایہ کاری مؤثر حل فراہم کرتی ہیں۔ دیگر قسم کی موٹروں کے مقابلے میں، جیسے سروو موٹرز، وہ عام طور پر زیادہ سستی ہوتی ہیں۔ مزید برآں، ان کے کنٹرول سسٹم کی سادگی اور فیڈ بیک سینسر کی عدم موجودگی ان کی لاگت کی تاثیر میں معاون ہے۔

آپریٹنگ رفتار کی وسیع رینج:یہ موٹریں بہت کم رفتار سے لے کر نسبتاً زیادہ رفتار تک وسیع رینج پر کام کر سکتی ہیں۔ وہ اچھا رفتار کنٹرول پیش کرتے ہیں اور ہموار سرعت اور سستی حاصل کر سکتے ہیں۔ رفتار کنٹرول میں یہ لچک انہیں مختلف رفتار کی ضروریات کے ساتھ ایپلی کیشنز کے لیے موزوں بناتی ہے۔

کمپیکٹ سائز:42mm فارم فیکٹر سٹیپر موٹر کے لیے نسبتاً کمپیکٹ سائز کی نمائندگی کرتا ہے۔ اس سے جگہ کی محدود ایپلی کیشنز یا آلات میں ضم کرنا آسان ہو جاتا ہے جن کے لیے کمپیکٹ اور ہلکے وزن کے ڈیزائن کی ضرورت ہوتی ہے۔

وشوسنییتا اور لمبی عمر:ہائبرڈ سٹیپر موٹرز ان کی وشوسنییتا اور استحکام کے لیے مشہور ہیں۔ انہیں کم سے کم دیکھ بھال کی ضروریات کے ساتھ طویل مدت تک مسلسل کام کرنے کے لیے ڈیزائن کیا گیا ہے۔

موٹر انتخاب کے تقاضے:

► نقل و حرکت/ بڑھتے ہوئے سمت

►لوڈ کی ضروریات

► اسٹروک کے تقاضے

►مشیننگ کی ضروریات کو ختم کریں۔

► صحت سے متعلق تقاضے

► انکوڈر فیڈ بیک کے تقاضے

► دستی ایڈجسٹمنٹ کے تقاضے

►ماحولیاتی تقاضے

پیداواری ورکشاپ

.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)